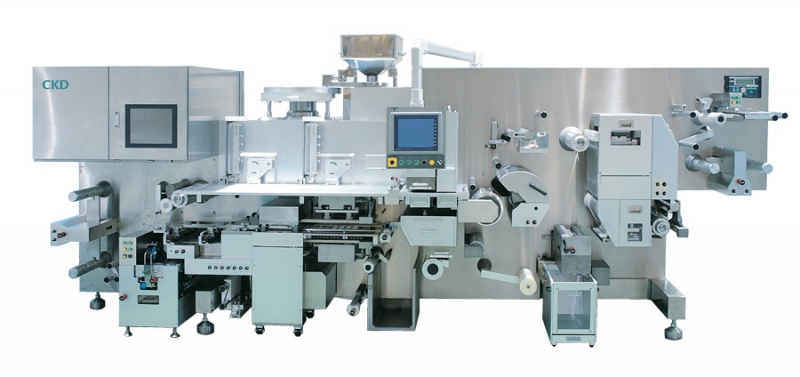

CKD – ECO Blisterparle2015-04-17T06:24:37+00:00

- CKD’s unique flim heating/forming/transferring/system has realized scrap volume reduction by 70%.

- CKD’s new plug assit forming methods and unique unit servo drive system have realized remarkable reduction of energy cost.

- 70% off Weight of forming dies reduces by 70%.

- Unit servo drive system has realized simple machine construction. 77% of machine volume is secured for working space.

- Machine adjustments is possible with digital settings even when the machine is in operation.

- Flat design helps superior visibility of foreign particle/wrong products and easy cleaning.

- Incorporation of amplifier box for flash patri (foreign particle inspection devices) with the machine saves more machine floor space.

- Comfortable working environment noise generated from the machine in 78dB.

- Consideration for safety by dividing the machine into zones.